Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

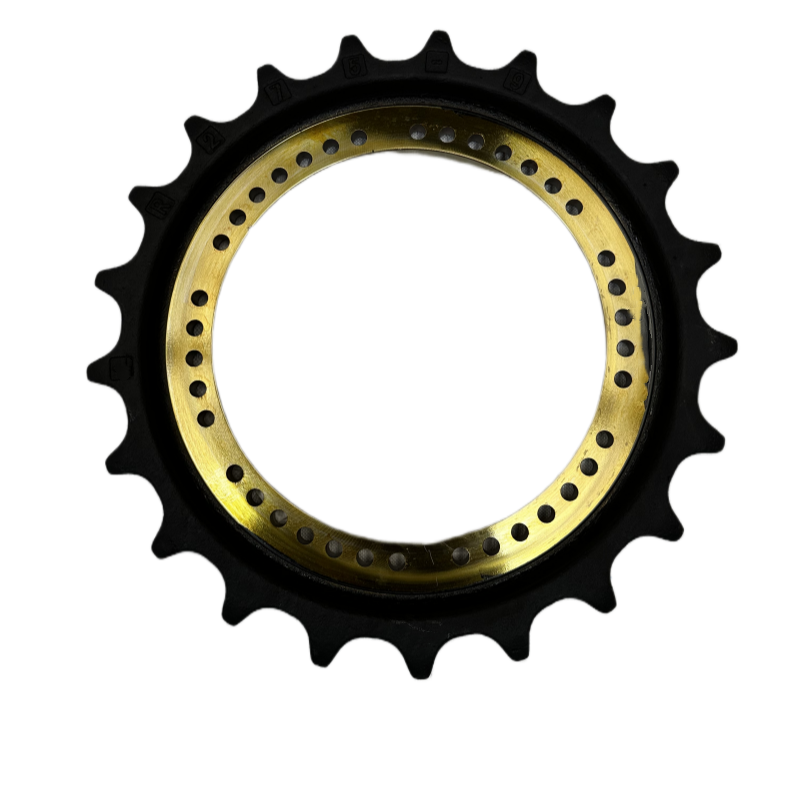

SPROCKET & SEGMENT

SPROCKET & SEGMENT

(29)Sprocket PC200-5 PC200-6 PC200-7 PC200-8 PC220-5/6/7/8 fits for Komatsu Excavator Shop Wholesale for New, Used and Rebuilt

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sprocket fits for Komatsu Excavator PC300-3 PC300-5 207-27-33222 Undercarriage Part Sprocket Pc300-6/7/8

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

HYUNDAI Sprocket R250LC-9 R275-9 21T 38H 410ID Excavator Sprocket Undercarriage Spare Parts for Various

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sprocket fits for Hitachi Excavator ZAX200-3/ZAX230/240 Ex200-3 Ex200-5 Ex200-6 Zax200 Zax210 1033091 Undercarriage spare parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sany Sprocket For SY215 SY335 SY365 Best SANY Excavator undercarriage parts China factory

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

VOLVO PARTS EC210D EC220D EC220E for Volvo excavator EC240b China SPROCKET Suppliers Manufacturers Factory

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sprocket fits for Sumitomo Excavator SH100 SH120-1 SH120-2 SH130 High quality undercarriage parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Hitachi Excavator Sprocket Ex300-6 Ex330 Ex350 Ex400 EX300-1/2/3 excavator undercarriage parts chain sprocket

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Undercarriage Parts Sprocket fits for Hitachi Excavator EX200-1 EX200-2/3/5/6 1018740 Made in China

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

EX135 EX135USR excavator sprocket 1026092 Hitachi Excavator Undercarriage parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Undercarriage Sprocket 1010325 for Hitachi EX100-3, EX120, EX110 China factory UH04-15 Uh065

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Ex60-5/Ex70/Ex90/Ex100/Ex100m EX60 Sprocket fits for Hitachi Excavator 9111033 Excavator Undercarriage Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.