Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

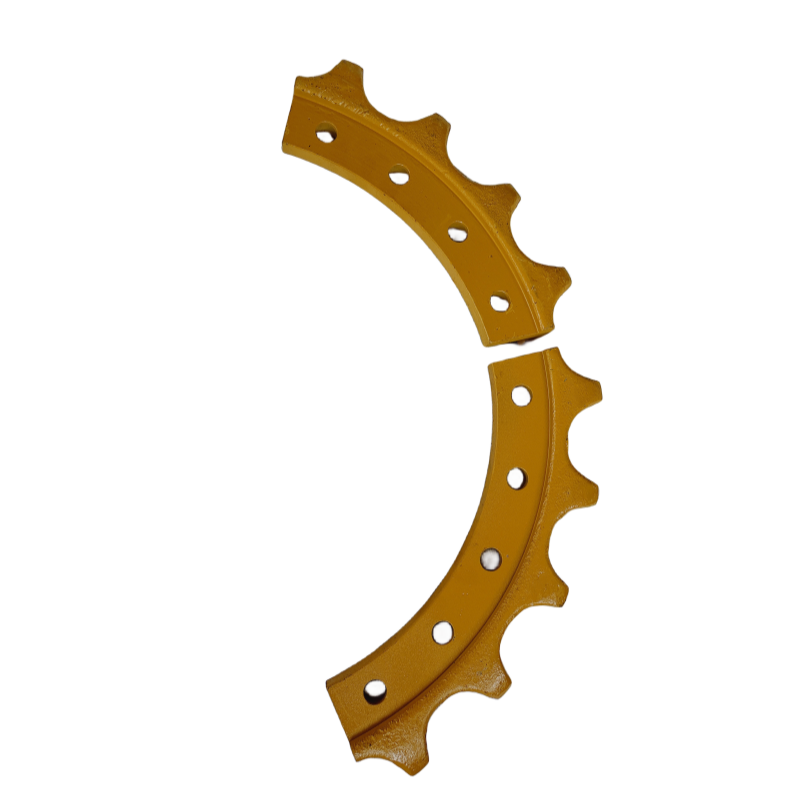

SPROCKET & SEGMENT

SPROCKET & SEGMENT

(29)Sprocket for Komatsu Dozer D20 D21 (Weld on type 25Teeth)

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Dozer BD2G BD2F BD2H BD2J 25/27TEETH sprocket drive sprocket for MITSUBISHI bulldozer undercarriage parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Komatsu 155-27-00151 D85A-18 Dozer Undercarriage Parts For Sprocket Professional Supplier Undercarriage Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

High Quality Undercarriage Parts Bulldozer Sprocket Segments Group D65/D85/D155 Komastu Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surfA thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.ace hardness ranges from HRC 50 to 56,depth from 6mm to 10mm.

For CAT D8L D8K D9K D9L Sprocket Segment 9w8178 7g6846 9p6843 Bulldozer Undercarriage Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Komatsu D50/D45/D53 Caterpillar D5M/D5L/D5B/D5C bulldozer Sprocket china undercarrige parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Caterpillar Cat Dozer D8h D8r D8K D8n D8c Undercarriage Parts Track Roller Track Chain and Shoe Idler Sprockets

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

D6D/D6C/D6E segment 3P1152 Dozer Sprockert Driving Wheel Segment Undercarriage OEM china factory

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

D4/D6D/D6H/D60E/D375/D475/D65/D68/D4/D5 Driving Wheel Segment Group Undercarriage Spare Parts For Komatu Caterpillar

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Mobile device Fit for IHI40NX Sprocket Excavator Mini Track Undercarriage Parts Top Quality Factory

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sprocket JCB/JS JCB130 JCB140 331/42434 Earthmoving Undercarriage Excavator Case 9010, 9010B, CX130

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Sprocket fits for Komatsu Excavator PC60-3 PC60-5 23T 12H 265ID PN 201-27-41110 china factory

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.