Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Ground Engaging Tools

Ground Engaging Tools

(42)Bucket Tooth Adapter for Komatsu PC500 Bucket Bolt-on Adapters

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

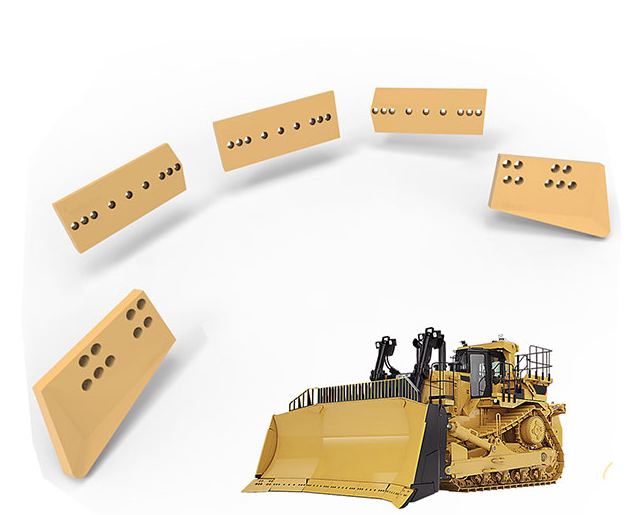

Bucket Cutting Edge From Dozer Professional Manufacturer

Cat cutting edges for dozer excavator and graders are specifically designed to provide a balanced system. Move more material, for longer, with less downtime.Superior breakage resistance through greater strength and max bottom and face wear protection. Cutting edges offer the best balance of abrasion and impact resistance for your wheel dozer or track dozer blades.

Komatsu PC400 excavator Bucket forged adapter 208-939-3120 Komatsu PC400-7 PC400-8 PC400LC-8 Adapter Plates 208-939-3120HD

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Komatsu Excavator Bucket Tooth Forged Adapter 205-70-5120 Wholesale Adapter 207-939-3120 PC300 Vertical Komatsu PC300-5/6/7/8

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Komatsu PC200 Excavator Forged Adapter 20Y-70-14180/3808-35/40 205-939-7120 20Y-70-14520 Excavator bucket Teeth china supplier

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Bucket Tooth Point E325 Excavator Tooth 1u3402 China Bucket Teeth J400 Rock tooth for CAT

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

616464 LC450HD Bucket Adapter E330 bucket adapter Excavator Parts Teeth Bucket Tooth E330 9W8452 Iu3452 7Y0358

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

2713-00032RC Forging Bucket Tooth Excavator 713y00032RC 2713-1234TL/DH360 Doosan Daewoo Bucket Tooth Pins And Retainer

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Caterpillar E320 excavator Bucket Teeth IU3352 CAT E320B/C/D J350 Rock Tip 7.5KG China 9N4352 replace

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

2713-9038 2713-1218 Dh220 Bucket Adapter for Dh220 DH225 SANY215 SY205/215 Teeth Bucket Excavator 2713-1217RC

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

CAT J250 (E312) Bucket tooth 1U3252RC 1U3252SYL Caterpillar Excavator parts E311 E312 E313 bucket tooth flat

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Excavator Wear Parts bucket forged adapter 616554 E345 E349 Excavator Bucket Teeth 6I6554 9J0174 J550 8E5559/3G9559

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.