Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

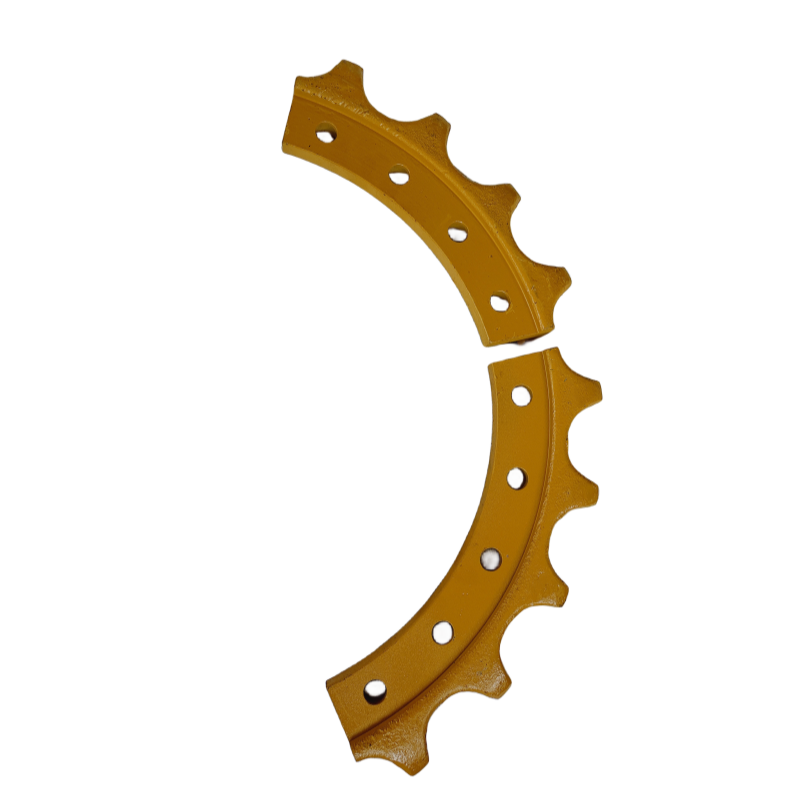

SPROCKET & SEGMENT

(29)Sprocket for Komatsu Dozer D20 D21 (Weld on type 25Teeth)

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Dozer BD2G BD2F BD2H BD2J 25/27TEETH sprocket drive sprocket for MITSUBISHI bulldozer undercarriage parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

Komatsu 155-27-00151 D85A-18 Dozer Undercarriage Parts For Sprocket Professional Supplier Undercarriage Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surface hardness ranges from HRC 50 to 56,depth from 6mm to 10mm. A thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.

High Quality Undercarriage Parts Bulldozer Sprocket Segments Group D65/D85/D155 Komastu Parts

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Adopting precision casting,guarantees the internal metallographic structure.The precision machining of mounting surface guarantees installed reliability and practical stability. The Sprocket surface hardness ranges from HRC 48 to 56,depth from 4mm to 10mm. The Segment surfA thorough study of the original drawing presenting the performance requirements of the various OEMs (Original Equipment Manufacturers) will allow us to manufacture all the different types of sprockets available on the market. The best solution will be applied to our production line after rigorous analysis of the drawings and heat treatment.ace hardness ranges from HRC 50 to 56,depth from 6mm to 10mm.

TRACK LINK

(9)Caterpillar High Quality Track Link for Used Bulldozer Cat D6d D3c D4h D5h D6h D7r D7h Track Link Assy Reference FOB Price

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. The quenching and tempering process ensures excellent mechanical properties, high strength, and superior wear resistance, bending resistance, and fracture resistance. Advanced automatic machining center ensures the accuracy of assembly dimensions. Automatic welding robots ensure that products have stable and good welding quality. We can also produce any requested parts based on your blueprints or samples.

OEM/ Original Shantui/Hitachi/Komatsu Bulldozer D60/D65/D80/D85/D155/PC60/P100/PC100/PC200/PC220 Excavator Track Link

Due to oil lubrication, the service life of oil rail connecting rods is longer than traditional ones. And through our professional heat treatment, quenching and tempering, our track links have good wear resistance and impact resistance. The quenching and tempering process ensures excellent mechanical properties, high strength, and superior wear resistance, bending resistance, and fracture resistance. Advanced automatic machining center ensures the accuracy of assembly dimensions. Automatic welding robots ensure that products have stable and good welding quality. We can also produce any requested parts based on your blueprints or samples.

20y-32-00013 Excavator PC200-5 Track Chain Track Link for Komatsu excavator Track Chain 45L/47L/49L PC200-5 PC220-5/6/7 PC230-6

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. The quenching and tempering process ensures excellent mechanical properties, high strength, and superior wear resistance, bending resistance, and fracture resistance. Advanced automatic machining center ensures the accuracy of assembly dimensions. Automatic welding robots ensure that products have stable and good welding quality. We can also produce any requested parts based on your blueprints or samples.

Track chain JCB JS200 JS210 JS220 JS240 49 links Jcb Excavator Undercarriage Parts Js200 Js210 Js220 JCB machines

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. The quenching and tempering process ensures excellent mechanical properties, high strength, and superior wear resistance, bending resistance, and fracture resistance. Advanced automatic machining center ensures the accuracy of assembly dimensions. Automatic welding robots ensure that products have stable and good welding quality. We can also produce any requested parts based on your blueprints or samples.

Track Shoe

(3)Track Shoe 600*10mm Fits for PC200 KM1846/800 Doosan DH200 DH220 DH225 Hyundai R220 Excavator Track Shoes

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Track shoe:Adopting 23Mn steel or 25MnB steel,which is high strength,good toughness,good wear resistance,strong impact resistance,and good hardenability.Having high comprehensive mechanical properties after heat treatment. We can also produce any requested parts based on your blueprints or samples.

964308 096-4308 track shoe fits caterpillar E200b/E320 Sh200 Js210 Sk200 Length 600mm/800mm Thickness 8mm/10mm

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. Track shoe:Adopting 23Mn steel or 25MnB steel,which is high strength,good toughness,good wear resistance,strong impact resistance,and good hardenability.Having high comprehensive mechanical properties after heat treatment. We can also produce any requested parts based on your blueprints or samples.

Track Shoes for bulldozers Dozer Excavator tracks manufacturer OEM quality Track, Shoes 510MM 560MM 610MM

The standard excavator style shoe offering good performance in most applications. Available for all sizes in varying widths.