Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Ground Engaging Tools

(42)BUCKET TEETH FITS KOMATSU PC60 20X-70-14160RC Bucket Teeth Standard Standard 1.8kg made in china forging factory

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Bucket Tooth PC100 Long Type P/N 20X-70-14160 For Komatsu Excavator PC100-5 PC100-6 PC130-8 forging factory

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Forging Casting Excavator Bucket Tooth Point Pc200Rc 205-70-19570RC Factory Direct Forged 5.6kg

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

207-70-14151 for PC300 Forged Bucket Teeth Point Heavy duty Komatsu Rock chisel bucket tooth 207-70-14151RC

High quality, high wear resistance, long service life. Utilizing the latest forging equipment and automatic heat treatment equipment to ensure installation reliability and practical stability. Comprehensive study of the original drawings has shown the performance requirements of various OEMs (Original Equipment Manufacturers), enabling us to manufacture all different types of bucket teeth available in the market. After rigorous drawing analysis and heat treatment, the best solutions will be applied to our production line.

Pin And Bushing

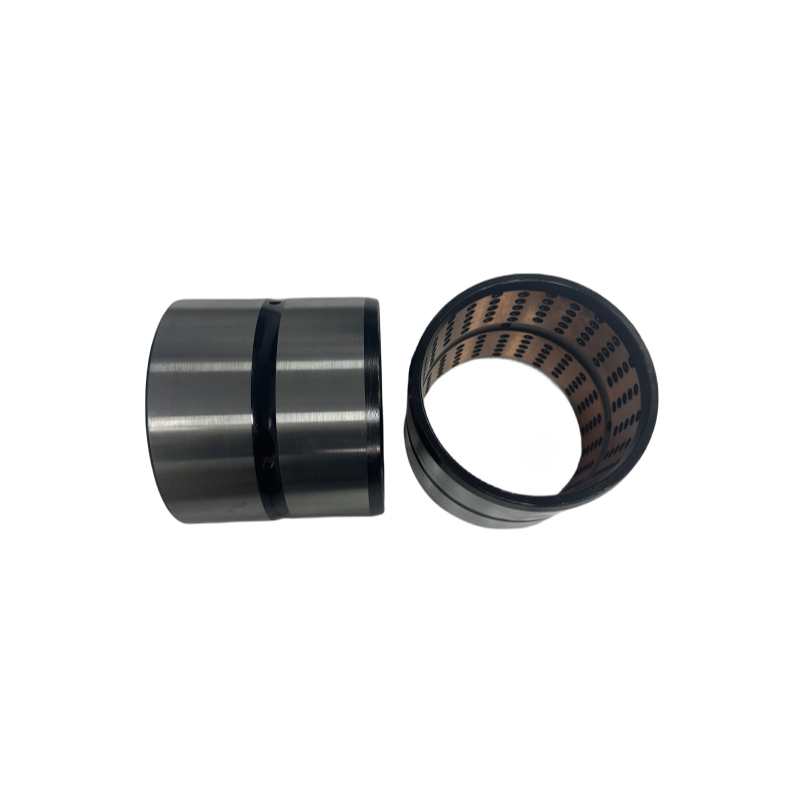

(19)Bushing Excavator Bucket Bushing Backhoe Bushing Bulldozer Bushing Grader Bucket Bushing Bearing-Sleeve suit for Caterpillar

Terris high-quality accessories are well-known in the industry and are your most reliable accessories supplier. Steel sleeve ------ high quality/high precision/long life Quanzhou Terris Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of chassis parts for various construction machinery such as excavators and bulldozers. We produce more than a thousand types of engineering machinery bushing series with an inner diameter of φ30-180 . The material is carbon alloy and carburized. The hardness is HRC56-62. We can produce products according to the drawings and processing requirements of customers. The bushings produced by our company have certain advantages, especially in situations where there is high impact and a lot of dust, but effective sealing cannot be achieved. At the same time, various types of oil holes and oil grooves are designed, which can not only meet the needs of oil passage, And it can effectively bury the dust, thereby increasing the service life of the bearing. Through different heat treatment methods, it can meet both wear resistance and high impact requirements. Shaft sleeve: The shaft sleeve is generally used in conjunction with the bucket shaft. Plays the role of fixed and sliding bearings. The diameter is generally: 30-180mm. Its operation is smooth, reliable and noiseless. Under liquid lubrication conditions, the bushing surface is separated by lubricating oil without direct contact, which can also greatly reduce friction loss and surface wear. 1 ) Internal texture type: straight groove, eight-shaped groove, hole-shaped groove, spiral groove, composite groove, etc. 2 ) Heat treatment A ) The hardness is HRC45-48, generally used for processing medium carbon steel and medium carbon alloys. B ) After surface carburization, the hardness is HRC56-62. It is generally used for the treatment of low carbon steel and low carbon alloy steel. Our company can specially customize according to user requirements and specific models.

SHoneycomb straight sleeve

Terris high-quality accessories are well-known in the industry and are your most reliable accessories supplier. Steel sleeve ------ high quality/high precision/long life Quanzhou Terris Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of chassis parts for various construction machinery such as excavators and bulldozers. We produce more than a thousand types of engineering machinery bushing series with an inner diameter of φ30-180 . The material is carbon alloy and carburized. The hardness is HRC56-62. We can produce products according to the drawings and processing requirements of customers. The bushings produced by our company have certain advantages, especially in situations where there is high impact and a lot of dust, but effective sealing cannot be achieved. At the same time, various types of oil holes and oil grooves are designed, which can not only meet the needs of oil passage, And it can effectively bury the dust, thereby increasing the service life of the bearing. Through different heat treatment methods, it can meet both wear resistance and high impact requirements. Shaft sleeve: The shaft sleeve is generally used in conjunction with the bucket shaft. Plays the role of fixed and sliding bearings. The diameter is generally: 30-180mm. Its operation is smooth, reliable and noiseless. Under liquid lubrication conditions, the bushing surface is separated by lubricating oil without direct contact, which can also greatly reduce friction loss and surface wear. 1 ) Internal texture type: straight groove, eight-shaped groove, hole-shaped groove, spiral groove, composite groove, etc. 2 ) Heat treatment A ) The hardness is HRC45-48, generally used for processing medium carbon steel and medium carbon alloys. B ) After surface carburization, the hardness is HRC56-62. It is generally used for the treatment of low carbon steel and low carbon alloy steel. Our company can specially customize according to user requirements and specific models.

China Bucket Bushings Manufacturers and Factory excavator 35 40 45 50 55 60 horse New Bucket Pin Bush Bushing

Terris high-quality accessories are well-known in the industry and are your most reliable accessories supplier. Steel sleeve ------ high quality/high precision/long life Quanzhou Terris Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of chassis parts for various construction machinery such as excavators and bulldozers. We produce more than a thousand types of engineering machinery bushing series with an inner diameter of φ30-180 . The material is carbon alloy and carburized. The hardness is HRC56-62. We can produce products according to the drawings and processing requirements of customers. The bushings produced by our company have certain advantages, especially in situations where there is high impact and a lot of dust, but effective sealing cannot be achieved. At the same time, various types of oil holes and oil grooves are designed, which can not only meet the needs of oil passage, And it can effectively bury the dust, thereby increasing the service life of the bearing. Through different heat treatment methods, it can meet both wear resistance and high impact requirements. Shaft sleeve: The shaft sleeve is generally used in conjunction with the bucket shaft. Plays the role of fixed and sliding bearings. The diameter is generally: 30-180mm. Its operation is smooth, reliable and noiseless. Under liquid lubrication conditions, the bushing surface is separated by lubricating oil without direct contact, which can also greatly reduce friction loss and surface wear. 1 ) Internal texture type: straight groove, eight-shaped groove, hole-shaped groove, spiral groove, composite groove, etc. 2 ) Heat treatment A ) The hardness is HRC45-48, generally used for processing medium carbon steel and medium carbon alloys. B ) After surface carburization, the hardness is HRC56-62. It is generally used for the treatment of low carbon steel and low carbon alloy steel. Our company can specially customize according to user requirements and specific models.

Wholesale Caterpiilar Excavator Bucket Teeth Pin and Retainer for Bucket Tooth and Adapter

HIGH QUALITY,HIGH ACCURACY,LONG SERVINCE LIFE. We focus on the efforts in the areas of BUCKET TEETH, ADAPTERS, and NEW-TYPE DEVELOPMENT. The teeth and adapters could replace the original parts of CATERPILLAR, KOMATSU,JCB, ESCO, KOBELCO, HYUNDAI, HITACHI,DAEWOO and so on. Our company can also provide the most satisfactory OEM FORGING products according to the customers drawings and requirements.